Silicon Steel, Cobalt Iron, Amorphous, Nanaocrystalline, SMC -- The advantages of five soft magnetic materials in new motors

With high magnetic permeability, low coercivity, the soft magnetic materials are easily magnetized and demagnetized. They are widely used in motor stators and rotor cores to guide magnetic flux and complete electromagnetic energy conversion in motors. With a global annual production of about 10 million tons, accounting for 80% of the soft magnetic material market, traditional non oriented silicon steel is still the dominant material for motor iron cores.

During increasing demand of high-efficiency, low loss, and small high-power density motors in emerging fields like new energy vehicles, electric aviation, high-speed motors, and axial flux motors, the limitations of traditional silicon steel materials in high frequency and low loss performance are gradually becoming apparent.To improving the performance of motors, the industry is actively developing and applying various new soft magnetic materials, including:

l silicon steel alloys

l cobalt iron alloys

l amorphous alloys

l nanocrystalline alloys

l soft magnetic composite materials (SMC)

A) . Silicon Steel Alloys

Currently, the silicon steel is the most widely used soft magnetic material for motors, its composed of IRON & 1%~3% silicon, as well as a trace amount of aluminum, manganese, etc. The non-orient silicon steel can provide isotropic magnetic properties, which suitable for motors' rotating magnetic fields request, while the oriented silicon steel is mainly used for unidirectional magnetic flux transformer cores.

The silicon steel material magnetic saturation flux density around 1.5~2.0T. It’s not highest value among different soft magnetic materials, but can meet most motors’ magnetic flux requirements. Facing the higher fundamental frequency & lower losses in high-speed motors, silicon steel materials are also keep continuously improving, as below two point:

a). High silicon content silicon steel

High silicon content silicon steel can reduce eddy current losses. Commercialized high silicon steel's silicon content can reach as high as 6.5%, with significantly improved resistivity & hardness, perfect for higher frequency & speed operation conditions in high-speed motors. Research has shown that 6.5% silicon steel in high-speed synchronous reluctance motors has lower iron loss than traditional silicon steel, and show advantages in 400Hz high frequency traction motor testing.

The disadvantage of high silicon steel is that excessive silicon makes the alloy brittle.

High silicon steel sheets can be produced through processes such as chemical vapor deposition and diffusion annealing, but with high energy consumption & high cost.

b). Thinner silicon steel sheet

At another hand, reducing the thickness of silicon steel sheets is a trend.

Ultra-thin silicon steel sheets could reduce unit thickness eddy current losses. Presently, high-efficiency motors & generators have adopted 0.1~0.3mm thickness thin silicon steel sheet, which exhibit significantly lower core loss at frequencies that several times higher than the power frequency.

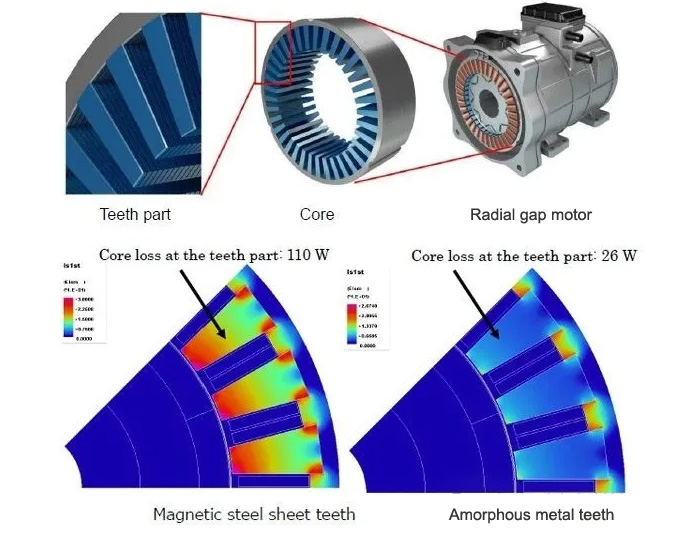

Hitachi Metals has developed a prototype drive motor that introduces amorphous materials into the traditional silicon steel stator teeth to reduce iron loss. The measured efficiency has reached 97.2%, equivalent to the ultra-high efficiency IE5 level. For mature materials like silicon steel, there is still potential to meet the high-performance requirements of new era motors through material and design innovation.

B) . Cobalt Iron (Fe-Co) Alloys

Fe-Co base Alloy is a soft magnetic alloy that adding high proportion cobalt elements into the iron base material, with extremely high saturation magnetic flux density. At room temperature, the magnetic saturation strength of 35% Co-65% Fe alloy can reach over 2.0T. This means that the iron cobalt material allows for higher magnetic flux density operation, significantly improving the torque and power density of the motor.

For small high-power density motors that pursue extreme performance, the advantages of reduced material usage and volume reduction brought by high saturation flux are very significant. Fe-Co base alloy also has excellent mechanical properties, with the highest strength among conventional electrical steels. Capable of supporting high-speed rotating components, some high-speed rotors use cobalt iron alloys for their iron cores to balance strength and magnetic performance.

During high cobalt content, the Fe-Co base alloys are very expensive and generally used in extremely performance requirements & cost are not sensitive situations. Typically:

l Aircraft motors and generators in the aerospace field

l Underground motors and generators in oil exploration such as oil well drilling and production

l Special electric and hybrid power systems in motor sports

l Magnetic levitation bearings, flywheel energy storage, and other high-speed rotating components with high magnetic flux

C) . Amorphous Alloys

Amorphous alloy is a soft magnetic material formed by the rapid cooling process that causes disordered solidification of metal atoms. Typically amorphous alloy is composed of Iron-Silicon-Boron, with an extremely think thickness about 0.02~0.03mm. The main prominent advantage of amorphous material is their extremely low core loss. During to being one order of magnitude thinner than silicon steel sheets and having a resistivity about triple times that of silicon steel, the eddy current loss of a single sheet is significantly reduced, and the hysteresis loss is also very low. Hitachi Metal report that the unit iron loss of amorphous metals is only 1/10 or even lower than traditional electrical steel.

Another characteristic of amorphous alloy is its excellent high-frequency performance.The extremely low loss characteristic has been widely used in high-frequency electronic transformers, switching power supply inductors, etc. For motors, the low loss advantage of amorphous material is more pronounced under high-speed operation or high frequency excitation.

The 11KW prototype motor developed by Hitachi Metals adopts an amorphous tooth structure, achieving a high efficiency of 97.2%.

D) . Nanocrystalline Alloys

Nanocrystalline alloy is a soft magnetic material formed by the precipitation of nanoscale grains from amorphous materials in their initial state after appropriate heat treatment. The soft magnetic properties of nanocrystalline material are further improved compared to ordinary amorphous materials: higher magnetic permeability, lower losses, and the magnetic saturation strength can be improved to a certain extent by adjusting the composition and process.Typically Fe-base nanocrystalline material’s saturation magnetic flux density range from 1.2T to 1.5T, slight lower than the high-quality silicon steel 1.8T.

Nanocrystalline alloys have high magnetic permeability & low core loss at high frequency, even operate efficiently at KHz frequencies with minimal thermal loss. Based on research, nanocrystalline motors’ operating efficiency could exceed 95%, even reach up to 98%,which higher than traditional silicon steel motors significantly.

Currently, nanocrystalline material widely used in electronic components like high frequency transformer, CMC, current transformers. But still of research & development in motor application field.

After heat treatment, the nanocrystalline strips is too brittle to be stamped. It’s difficult to directly application in large motors because almost nanocrystalline products in the markets ar circular or E-shaped magnetic cores, with small diameter range from centimeters to ten centimeters.

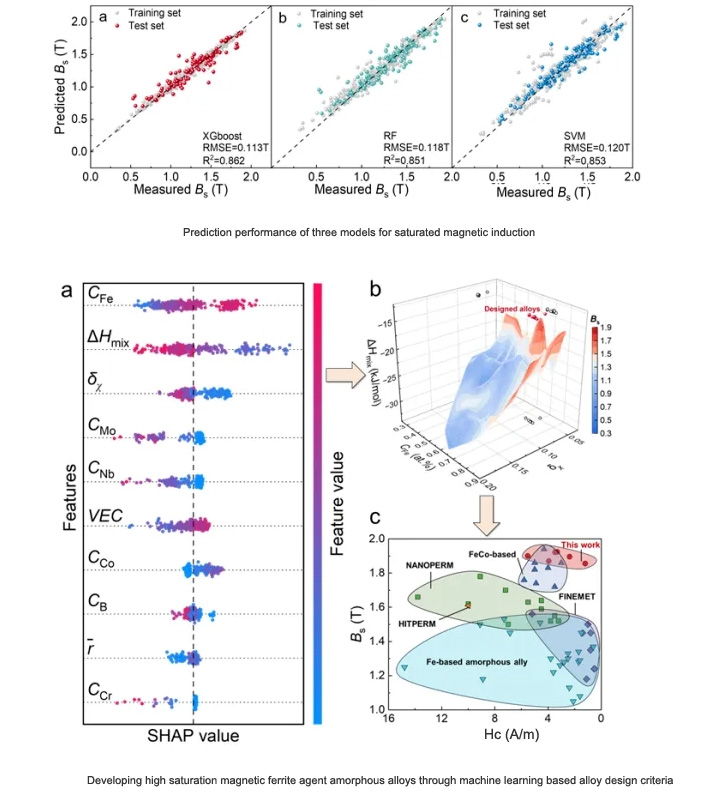

The research and development of new high saturation nanocrystalline alloys is accelerating. The Chinese Academy of Sciences has successfully developed a Fe based amorphous/nanocrystalline alloy with saturation magnetic induction of 1.85-1.92T. By introducing a certain amount of cobalt and nickel and controlling elements such as boron and phosphorus, these new alloys achieve much higher magnetic saturation than previous iron-based amorphous alloys, while maintaining extremely low coercivity.

E) . soft magnetic composite (SMC)

Soft Magnetic Composite (SMC) is a material formed by compressing pure iron powder particles through insulation coating. Each iron powder particle is isolated by an insulation layer and is usually formed by powder metallurgy compaction sintering or bonding solidification.

The most significant feature of SMC is the three-dimensional degree of freedom in magnetic circuit design.

Traditional motor iron cores are stacked with two-dimensional flat sheets, which can only be stacked along the direction of the punching plane, while SMC can directly press complex shaped integral or split magnetic cores, making three-dimensional magnetic flux paths possible.

This provides great convenience for new motor topologies, as designers can conceive novel magnetic circuits such as axial flux and radial axial mixed flux, breaking through the limitations of laminated stator topologies.

Axial flux motors and claw pole motors are typical beneficiaries of SMC topology. In axial flux machines, the three-dimensional distribution of magnetic flux is complex and difficult to implement with laminations, while SMC can close the magnetic flux in three directions. Traditional claw pole motors, due to their complex rotor claw pole structure, cannot be realized using layered silicon steel and have to use integral steel components, resulting in severe eddy current losses and limiting speed and size. After introducing SMC, the claw pole structure can be directly formed by powder metallurgy, eliminating the circulating eddy currents inside the claw pole and greatly improving the power density and speed range of the motor.

Another advantage of SMC materials is their extremely high electrical resistivity and low eddy current losses.

At frequencies above 1 kHz, the eddy current loss of SMC cores is much smaller than that of silicon steel laminated cores. SMC has significant loss advantages over traditional silicon steel in high-frequency motors.

In the axial magnetic flux topology, the magnetic flux exits the plane through the thickness direction of the iron core. If silicon steel laminations are used, a large amount of eddy current loss will be generated due to the perpendicular cutting of the magnetic flux on the laminated surface, which may even offset the performance improvement brought by the axial topology. The anisotropic insulation structure of SMC perfectly solves this problem, enabling axial flux motors to fully unleash the potential of 3D magnetic circuits.

The axial flux permanent magnet motor of YASA company in the UK adopts a yokeless segmented stator structure, which is considered to use SMC or separated tooth technology to achieve ultra-high torque density and is adopted by supercar models such as Ferrari.

Recently, Torev collaborated with MPP to develop an SMC stator axial flux motor, which maximizes the advantages of SMC materials

The SMC integrated stator length they designed is only one-third of that of traditional radial motors, reducing the overall weight by about 30%. However, the peak efficiency of the motor is as high as 98% (150 kW power level), and due to low losses, the motor is less likely to generate heat, thereby extending the range of electric vehicle batteries.

More meaningfully, SMC stator is easy to combine with prefabricated windings, achieving automated assembly. Due to the full utilization of magnetic steel, the manufacturing cost is reduced by about 30% while reducing the amount of rare earth permanent magnets used. This proves that the application of SMC in the drive motors of new energy vehicles is feasible and competitive.

The development of soft magnetic material technology and motor design is mutually empowering. The emergence of new materials has provided possibilities for motor topology and higher performance, and the demand for new motor applications is driving material manufacturers to continuously break through the performance limits of soft magnetic materials. It can be foreseen that in the context of the explosive demand for efficient motors in industries such as industry, transportation, and energy, more cases of combining new materials with motor design will emerge in the future.

Categories

New Blog

Call At :

Call At :

Tel : +86-20-85649266

Fax : +86-20-85649263

Email Us :

Email Us :

Email : derful@coilcore.com

Address :

Address :

A402 Zhuangyuangang Industry Park, No.186 Qishan Road, Tianhe District, Guangzhou 510663

© Copyright: 2026 Guangzhou Amorphous Electronic Technology Co.,ltd. All Rights Reserved. 粤ICP备2021057165号

IPv6 network supported